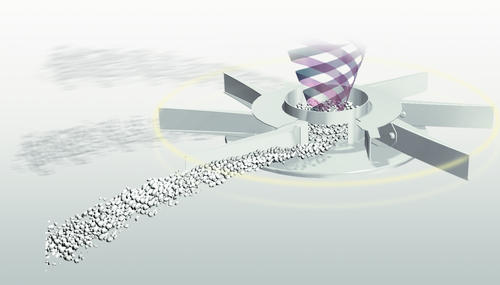

Kverneland Exacta TL GEOSPREAD

GPS Controlled Intelligent Machine Solutions

The Exacta TL GEOSPREAD is equipped with two actuators on each dosing unit. One of these actuators controls the setting of the discharge point of the dosing cup onto the disc (letter setting), the other controls the application rate. The GEOSPREAD system makes it possible to adjust the letter setting individually for both discs electrically from the tractor cab. This means the working width can be easily adjusted quickly and accurately just by touching the ISOBUS terminal!