Kverneland 4332 CT| 4332 CR

Trailed Mower Conditioners with Centre Pivot Drawbar

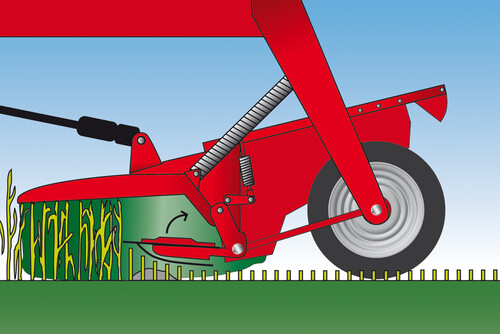

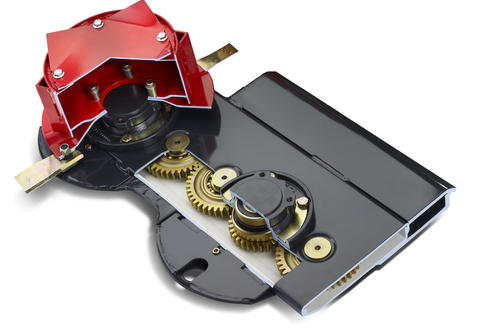

Including features such as SemiSwing conditioner, low maintenance cutterbar, SuperFloat suspension, BX Auto-Swather belt and FlipOver widespreading, Kverneland 4300 series machines are ready to meet every request with exceptional performance