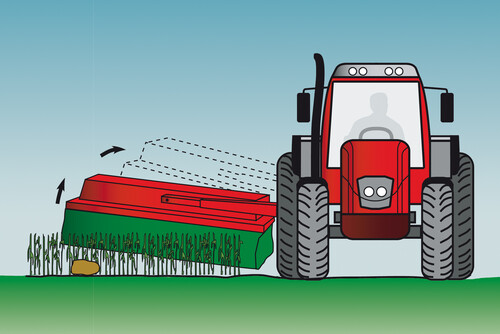

Kverneland 3232 MN

Centre Mounted Mower Condtioners

Kverneland offers the centre mounted mower conditioner, 3232 MN, in working width of 3.16m.

There is an optional parking stand for easy, compact storage. Storage is made easy and convenient, requiring a minimum of space during winter storage.