Kverneland 2832M| 2836M| 2840M

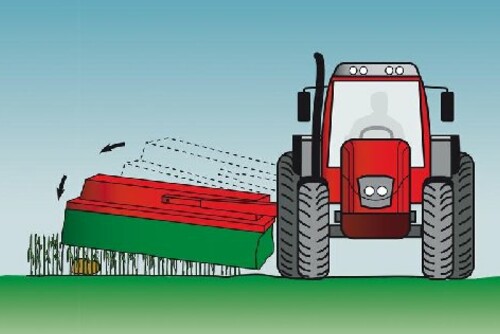

Centre Mounted Disc Mower

Kverneland 2800 M rear mounted range boast an extensive 2.80-4.00m working width with corresponding weights of only 806-940kg, which means the machines can be operated with tractors starting from only 40hp, making these very attractive machines for farmers with smaller tractors, who still needs to cut substantial areas. Paired with the Kverneland 2828 F or 2832 F front mounted machine the joint working width is up to an amazing 6.80m.

There is an optional parking stand for easy, compact storage. Storage is made easy and convenient, requiring a minimum of space during winter storage.